Fulfilling a successful lift, and when we say successful we mean safe and efficient, is all in the planning. Have you weighed your item? How many attachment points do you need? What’s the clearance height? How high is the lift? What type of environment is the lift taking place?

How to choose the right lifting sling

These are just a few of the questions that you must ask yourself before undertaking any type of lifting or rigging task. But here’s your first challenge… what type of sling do you need? It might seem like an easy answer, but we understand that sometimes there’s just too much choice, which leaves doubt in our minds.

The different types of lifting slings

At a basic level, there are three sling types – Chain/Alloy, Wire Rope, and Synthetic – Sounds simple enough right? But here’s where it might get overwhelming. Under the Alloy umbrella comes Chain and Mesh, while under Synthetics you have Web, Round, and Rope Slings. So which one is the right choice for you? Here, we look at where these sling types are best suited, enabling you to make an informed decision with safety, reliability, and efficiency at the core.

Chain Slings

If you’re in the market for true strength, Chain (typically Grade 100) should be your go to… YOU WON’T GET ANYTHING TOUGHER! There’s a reason they are the preferred choice for making those heavy-duty, aggressive, and repetitive lifts in basically any industry that’s exposed to harsh environments - high and low temperatures, corrosive etc. Think construction, chemical plants, foundries, steel manufacturing facilities, mining. All these types of environments simply tear through wire rope and synthetic slings like a hot knife through butter. But Chain Alloy stands up to the task…. Every time. In fact, they can be heated up to over 400°F, although working load limits must be reduced in accordance to manufacturers recommendations.

Available in 1-Leg, 2-Leg, 3-Leg, and 4-Leg variants, chains can be configured to suit your individual requirements, with a range of lengths up to 30ft; chain diameters of 3/8”, 1/4”, 5/8”, 5/16”, and 1/2”; and a variety of masterlinks and end fittings – they are truly customisable, with adjustable chain sling options also available. Certainly a huge advantage.

Furthermore, chain systems are completely repairable, eliminating the worry of any damage taken during the lifting process and can be load tested and re-certified after any repair processes, giving you total peace of mind that you’re compliant and safe.

Synthetic Slings

Synthetic Slings

Synthetic Slings are the more steady choice for delicate lifts, offering high levels of flexibility and strength, protecting those expensive loads from scuffs and scratches. Utilized commonly in construction and other general industries, as well as explosive atmospheres, they are relatively cheap and due the array of standard sizing options are a versatile choice.

The downside to synthetic slings is that they are susceptible to tearing and other means of damage that can weaken the structural integrity of the sling. And although easily replaceable, these types of slings are unrepairable. The second any damage is highlighted, they must be immediately removed from service. Daily checks must be undertaken, in fact, a sense check must happen prior to every single lift.

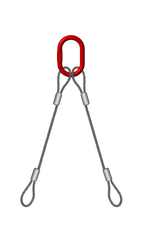

Wire Rope Slings

A popular choice in industries such as automotive, oil and gas, construction, and manufacturing, Wire Rope Slings can without doubt handle many rugged conditions through sheer strength, durability, and flexibility.

Before choosing a wire rope sling, it’s important to understand the different configurations of this type of sling, with materials and strand structure essential to different applications and lift types.

Available in single and multi-leg variations, again, wire rope slings offer some downfalls. They have a low strength to weight ratio, and due to their intricate construction, inspection is particularly difficult. In addition, they cannot be repaired, therefore replacement is the only option. Any type of misuse can cause kinking and abrasion. Careful consideration must be taken before introducing Wire Rope Slings to your assemblies.

We're Hear For You

We hope that may have cleared up some of the questions that you may have regarding lifting slings. As you now know, the combination of load type and environment dictate the type of sling you should use. Remember, safety should always remain your core principle, so don’t rush into a decision.

At SlingSmarter™, our knowledge and experience reaches further than just chains, we’re specialists in all aspects of lifting and rigging slings. So, if you have any questions, please don’t hesitate to contact one of our highly trained and knowledgeable specialists, who’re always on hand to advise you in the right direction.